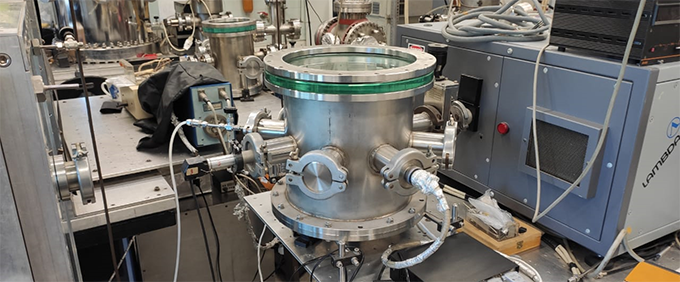

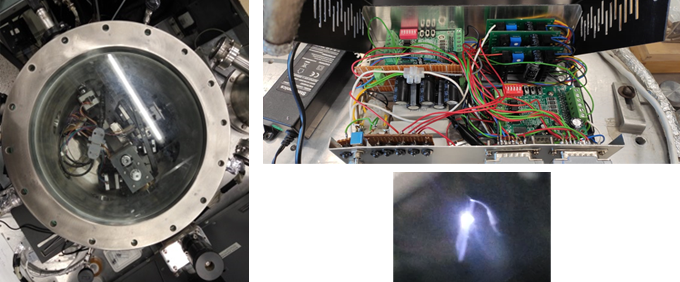

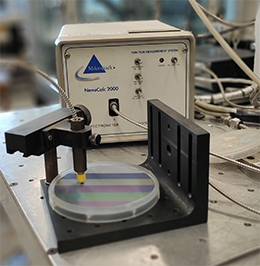

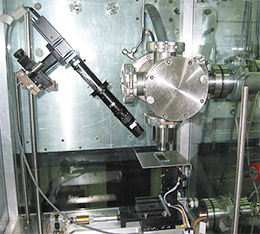

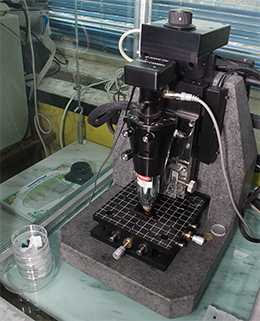

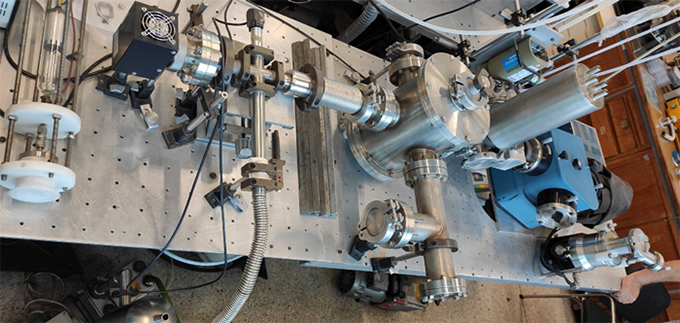

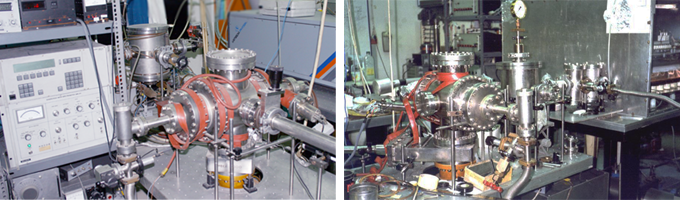

Vacuum Ultra-violet (VUV)-micromachining workstation, capable of processing different materials (from polymers to hard alloys) with ~2 μm resolution. A user-friendly software, (besides controlling the experimental parameters), has one additional degree of freedom that allows surface modification and processing with specified patterning.

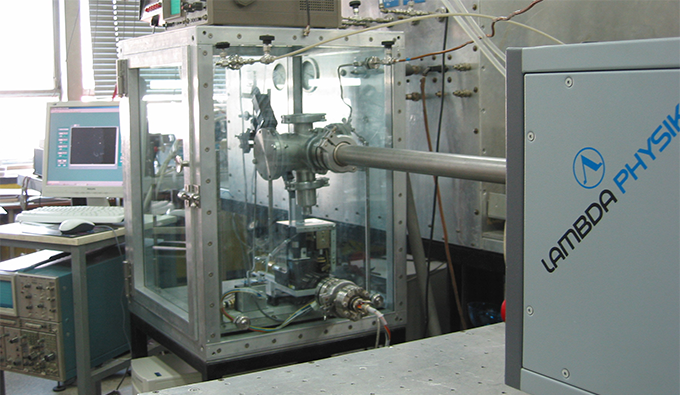

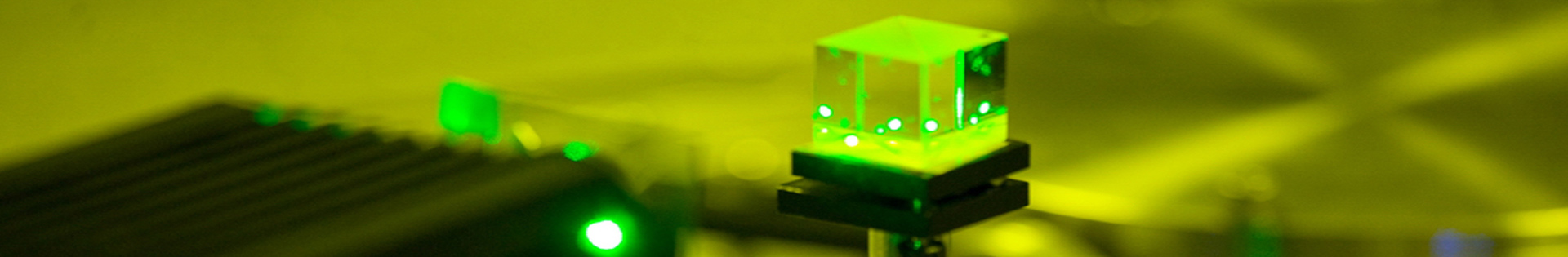

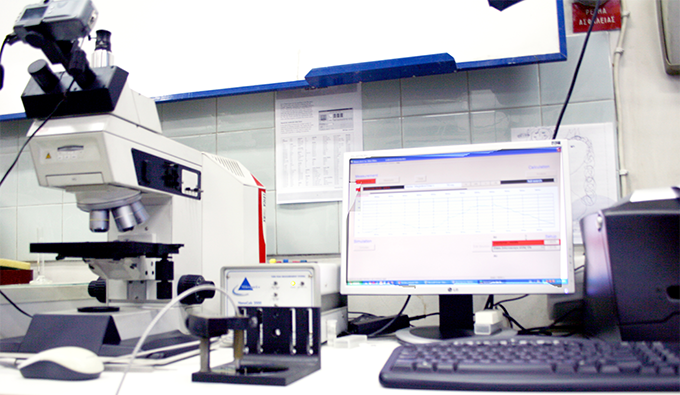

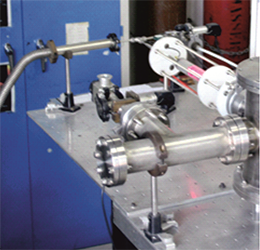

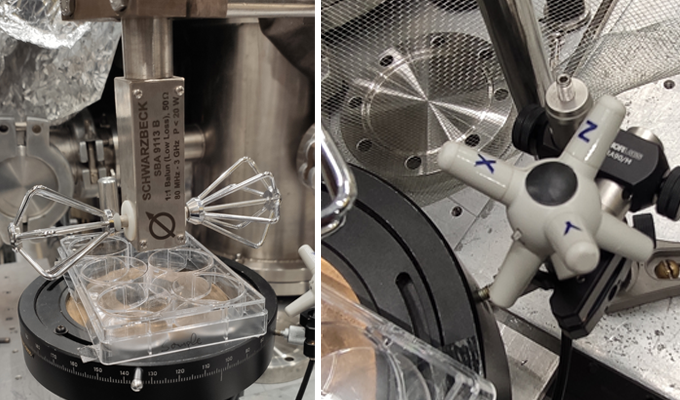

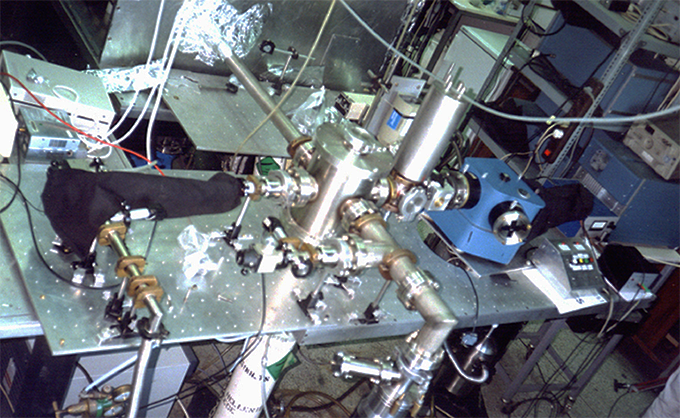

The main components of the system are: (1) The 157 nm molecular fluorine laser (by Lambda-Physik LPF 200). (2) The VUV high quality beam projection optics. (3) The computer-controlled lab-made X-Y-Z-θ motorized stage, combined with one CCD imaging system for real time imaging and automatic control. The system is operating inside a glass chamber in N2 environment for surface processing and structure patterning. Applications include surface modification and functionalization of thin polymeric films for sensing and space applications and DNA chip manufacturing.